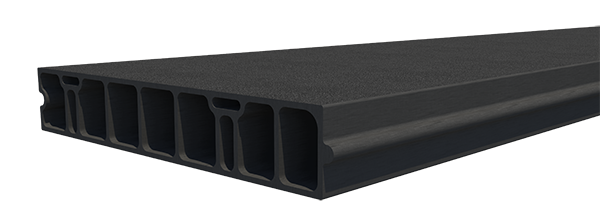

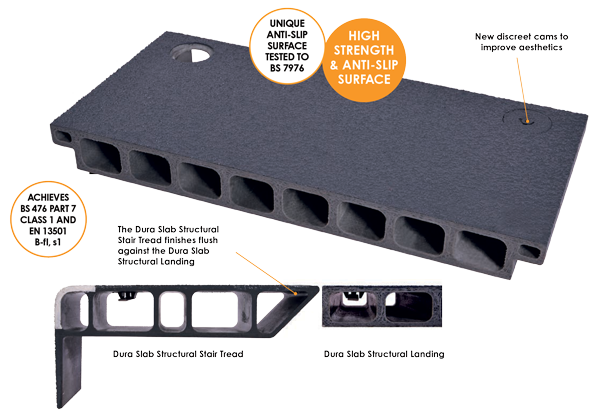

Dura Platform is a breakthrough composite product which solves all of these challenges and more in record time! Made from Glass Reinforced Plastic (GRP) which offers significant improvements over traditional alternatives such as concrete. It has been described as “game changing” by industry insiders and has won multiple awards.

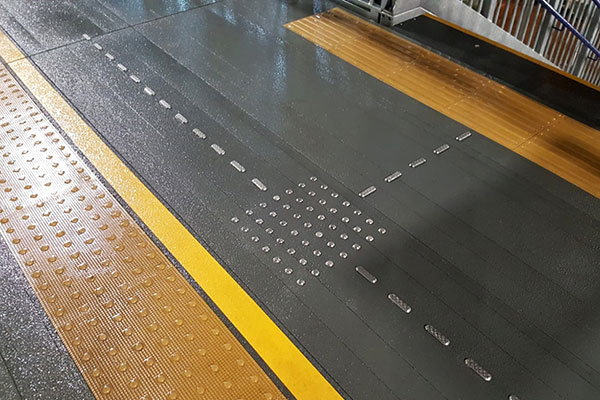

Dura Platform is an excellent choice for both new build and refurbishment projects and is fast becoming a viable rival for traditional materials such as concrete, steel and tarmac. With over 20,000 square metres already successfully installed at railway stations across the globe, Dura Platform is now available in Australia and New Zealand.

Dura Platform can span up to an industry-leading 3.2m clear span and is capable of being man-handled, eliminating the need for costly RRVs or heavy lifting equipment. Its hidden fixing system minimises trip hazards, and the platform is also crankable to create an instant 1:40 fall to manage drainage.

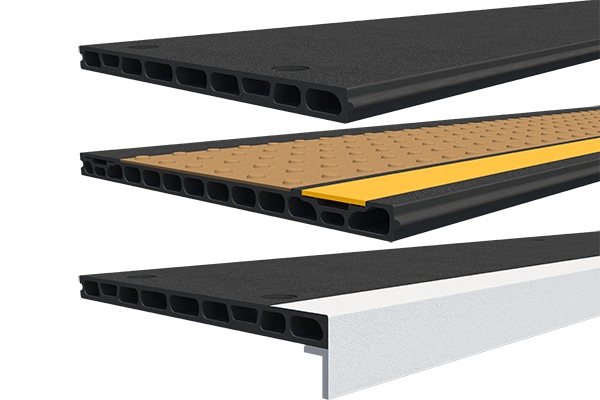

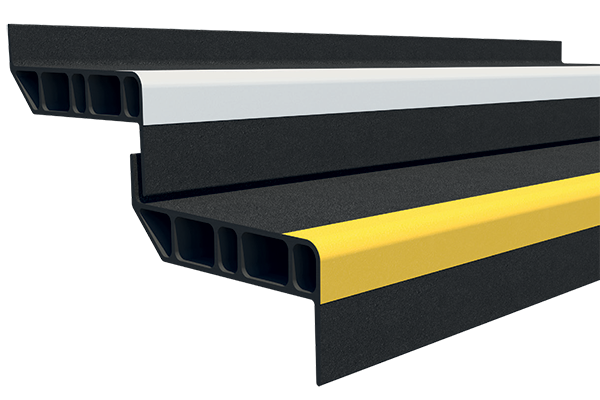

Our latest innovation for Dura Platform includes the option of a solid surface on the 600mm plank which removes the need for longitudinal cover plates to cover the fixings and provides a uniform, aesthetically pleasing finish.